Dissolve Scale • Prevent Build‑Up • Preserve Equipment Efficiency

At SWAS Consultants, we offer advanced de‑scaling and anti‑scalant chemical solutions designed for industrial systems, including boilers, chillers, heat exchangers, cooling towers, pipelines, and RO membranes. Our dual-approach treatments dissolve existing scale while preventing new deposits—maximizing heat transfer efficiency, reducing downtime, and extending the life of your assets.

Understanding Scale, De‑Scaling & Anti‑Scaling

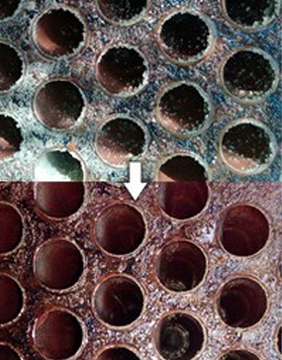

Gard water buildup like calcium carbonate, magnesium, iron oxides, and silica forms on heated surfaces, impairing heat transfer and increasing energy needs

(e.g., inhibited acids: hydrochloric, sulfamic, citric) safely dissolve thick scale layers

(phosphonate or polymer-based) prevent crystal formation at very low dosages (ppm), maintaining system cleanliness and efficiency

De-scaling chemicals are acid-based or blended formulations used to dissolve and remove:

Calcium carbonate (CaCO₃) scale

Silica and iron deposits

Magnesium salts and sludge layers

Rust and mineral residues

These unwanted deposits typically form in boilers, condensers, cooling towers, heat exchangers, chillers, and pipelines, reducing system performance and risking equipment failure if not treated.

We provide a range of de-scaling chemicals for both mild and severe scale conditions. Our product line includes:

Formulated with inhibited acids (e.g., hydrochloric, sulfamic). Safely dissolve heavy scale in condensers, heat exchangers, and pipelines. Available in standard and low-foaming options

Non-fuming and safe for most metals. Effective on mild to moderate scale. Easy to handle and compatible with manual or CIP systems

Biodegradable and food-safe options for F&B and pharmaceutical applications. Gentle yet effective against mineral build-up

Used after descaling to balance pH and neutralize residual acid. Protect downstream systems and ensure safe discharge

Our de-scalers are used in:

Boilers & economizers

Cooling towers & chillers

Heat exchangers (plate & shell-and-tube)

Condensers & air compressors

Reactors, jackets, and pipeline circuits

RO membrane pre-cleaning (with specialized blends)

Improves heat transfer and energy efficiency

Reduces fuel and operating costs

Minimizes equipment corrosion and downtime

Extends equipment lifespan

Easy application with minimal disruption

Safe for use with most metal surfaces

Expert support for scale analysis and chemical selection

Customized de-scaling programs for different industries

Eco-conscious and low-toxicity formulations

On-site dosing, flushing, and system cleaning support

Full documentation & compliance with discharge norms

We don’t just sell chemicals—we offer end-to-end descaling services designed to maintain your operational excellence.

Our de‑scaling and anti‑scalant chemicals are essential for:

Boilers & economizers

Heat exchangers (shell‑and‑tube, plate, chiller, condenser)

Cooling towers & closed‑loop systems

RO/UF membranes

Pipelines and feedwater systems

Restored heat-transfer capacity and energy savings

Minimized interruptions with safe online cleaning

Lower maintenance costs and maintenance frequency

Extended life for membranes, tubes, and vessels

Reduced chemical usage and eco-friendly discharge